Plant

Tissue Culture

Unorthrodox

model in Commercial Micropropagation

A

new, advanced and efficient model

The

approach used to prevent culture contamination

makes all

the difference between

old

conventional model and our new advanced model

Most

of the present models rely heavily on:

clean air areas. facility under

positive pressure and air handling systems

central air conditioning to maintain

temperature control in Culture Incubation Rooms and

special construction designes to ensure thermal

insulation

Providing for racks to store and incubate

cultures and artificial lighting system

Use of expensive glassware/plasticware as culture

containers

Providing for expensive flooring and

several other expensive equipment which are supposed to

be absolutely essential part of the Technology.

All

this, unquestionably needs huge capital costs. In addition, all

these equipment consume high quantum of energy. No wonder, with

reference to this widely known and widely used model, commercial

micropropagation is quite correctly perceived as a wonderful,

exciting but very expensive proposition.

By

conservative estimates, the old model costs,

for annual

installed capacity of 5 million plants,

capital

cost of Rs. 35 million (About 0.8 million US $)

with a

conservative estimate of

cost of

production of Rs. 5 - 12 (0.11 to 0.27 US $) per plant

depending

on plant species.

However

Experience

of most of the established ventures tells that despite so much of

expenditure,

trouble

free operation is rarely achieved.

Things

have changed radically, however,

after

our rethinking which started about 12 years ago

We found that the energy guzzling

equipment contributed highest cost factor. This environment

control engineering is not necessary if principles of Bioprocess

Engineering are used. Centralized air conditioning,

artificial lighting, clean air quality in culture

incubation room are no longer necessary for large scale

culture production. The cultures can be incubated in

simple fan and pad green house in diffuse NATURAL LIGHT

in ambient air quality.

Use

of Bioprocess Engineering principles is not as simple as just

starting incubating cultures in open environment, nor is it an

overnight success.

As soon as you

expose cultures to the source of natural illumination, several

problems are encountered. Major problems being:

- Rise in

temperature

- Rise in

risk of contamination of all types

- Rapid loss of moisture from

cultures leading to drying out

Circumventing

these problems was not obviously an overnight success, much less

a cake walk. Years

of R&D has gone into devising methods to circumvent these

problems in large scale production and generate an easy to operate know-how. This package of

meticulously standardised practices constitutes our

New

Model of Commercial Micropropagation

This

has

already been validated by successful

production of hundreds of thousands of cultures in

regular production programmes in commercial facilities

having 10 clean workstations.

This

model is, now set to change

perspectives of global micropropagation business.

and

is

now available from us for a modest know-how fees.

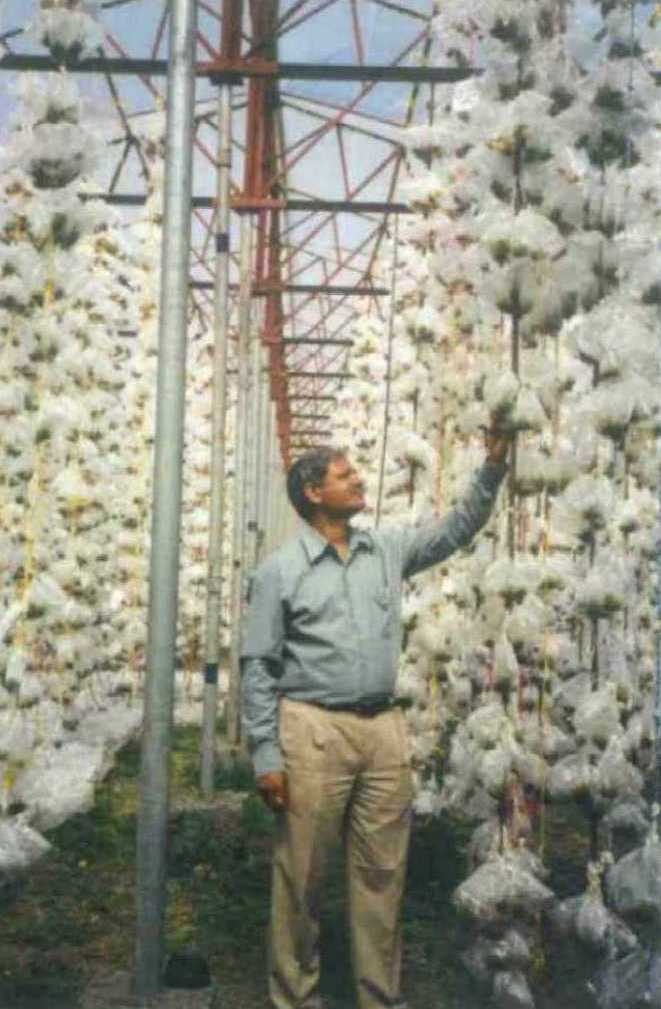

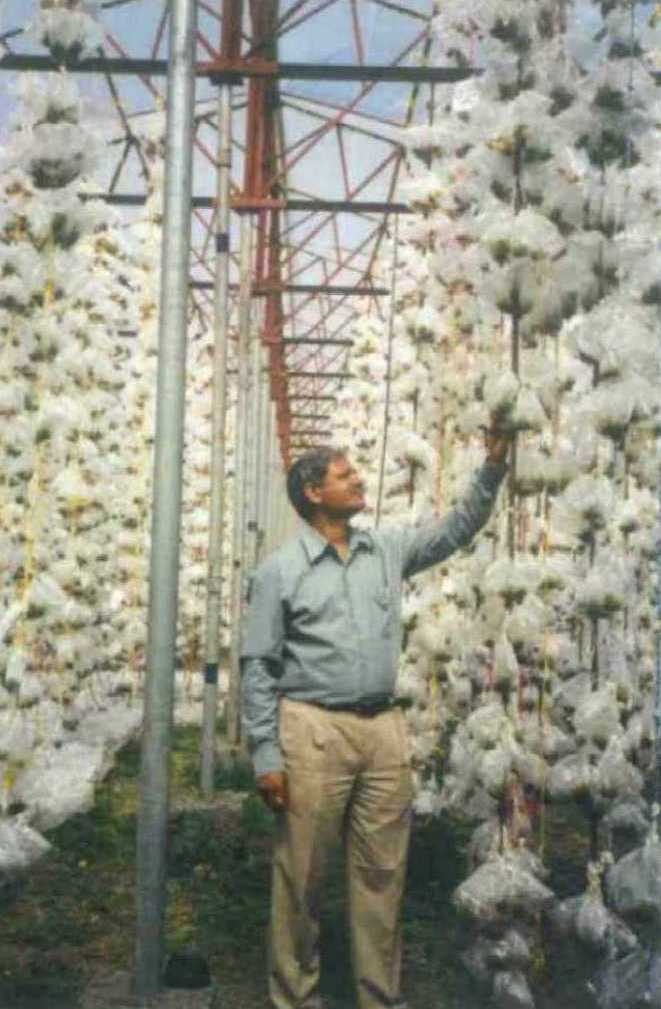

SALIENT

FEATURES OF NEW MODEL

Our new, advanced model, due to all the

reasons elaborated above, needs least modification of

ambient environment in Tropical and Sub-Tropical

countries. Culture room can be as simple as a

polyhouse, with a fan and pad arrangement at some places. This obviously

means

far

less capital as well as running expense and produces far more sturdy

plants of better quality because it is produced in

environment which is much nearer to its natural

environment in which it is supposed to perform in the

field.

Simple culture incubation

facilities of various scales: producing high quality

plants on large scale

|

Click

on the pictures for

notes and blow-up

No

artificial lights

- Natural light as

light source

- No air

conditioning

- No Class 10,000

air area

- Least or no

culture racks

- Simple/no flooring

- It can be a

Greenhouse too

|

|

| |

|

|

|

Result

- Semi-hardened,

- green, and

- sturdy plants

|

|

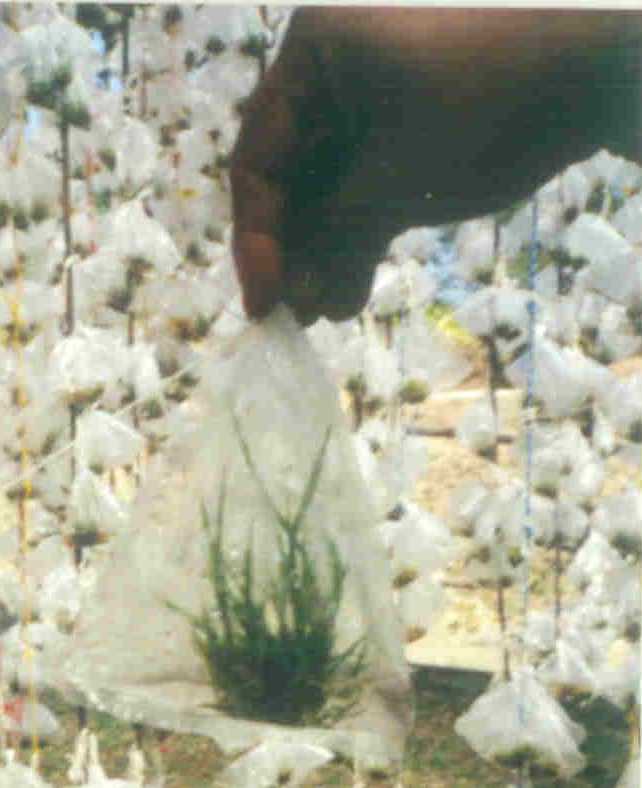

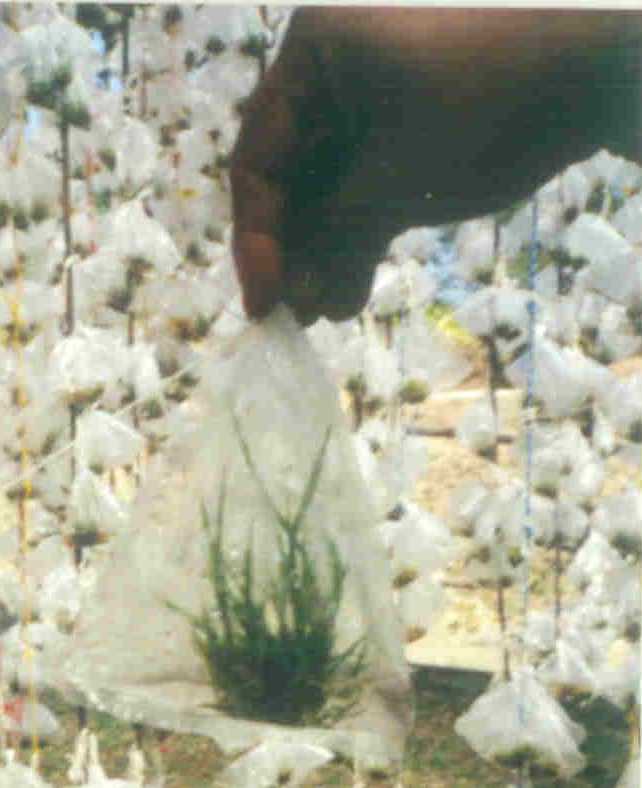

-

- Same

reasons make it possible to introduce innovative use of suitably

pretreated polybags as culture containers for production

instead of vessels made of glass or plastic. This measure

opens scope for adopting several measures which lead to increase in

process efficiency leading to cost reduction.

We further increased the efficiency of the

system by devising special handling techniques which lead

to phenomenal increase in throughput from the Laminar

Clean Air Flow workstations.

A very important additional collective

result of all above steps is that the plants developed in

this system are already semi hardened. Their need for

protection against desiccation in primary hardening phase

is limited to much shorter time. After a brief period of

protection, they can be further hardened in direct

sunlight and best possible degree of hardening is

achieved.

Better

efficiency in Hardening of plants

|

Cick on the pictures for

notes and blow-up

|

|

-

is an additional package available from us

under our consultancy, independent of whether you do or

do not choose to adopt our model. This package

envisages methods based on cytology, comparative

vegetative anatomy, microbiology and DNA based diagnostic

Molecular Biological methods to ascertain various quality

attributes for in-house quality control as well as for

third party based Quality Assurance Systems.

These tests will serve two important

purposes. First of all, producer will be able to control

his own production quantitatively as well as

qualitatively on direct scientific standards. Secondly, consumers will

know on what to rely upon. This will lend firm foundation

on which consumer confidence and legitimacy of the trade

can be based, both in domestic as well as international

markets.

We strongly recommend adoption of this

package also in conjunction of our model. Expenditure on

sophisticated quality control systems is more rational

than expenditure on environment control. Use of such

systems in Commercial Micropropagation industry is a

rarity.

It

is obvious that capital cost as well as running cost of

such a unit will be phenomenally low. This will change

the entire perception of global micropropagation business

as well as applications.

How

much low will it be indeed?

That

will depend on several locational factors

We

would help you work it out on case to case basis

Send

your querries with all relevent details

Preliminary

interactions are free

Do

not saddle yourselves as well as your customers with huge extra

cost which is not useful to both of you.

Also,

do not waste time and get tempted to reinvent the wheel on your

own.

We

offer the know-how on a modest consultancy fee which is much less

than what you will spend for standardising it independently

yourselves, with additional expense of few years and at loss of

opportunities that an early bird can muster in global

competitiveness and leadership in the business.

Acquire

our know-how today, take an unbeatable lead in Global

Micropropagation business and maintain it by resorting to

continuous improvement through R&D.

Acquire

a rare combination of

Process

Efficiency, Cost Effectiveness and Quality Attributes

For more

detailed discussion, click on following article:

New

Perspective in Commercial Micropropagation

E-mail: info@tissuecon.com